As we’ve mentioned in prior blog posts, high precision Doppler radial velocity (RV) measurements require extraordinarily stable instruments to measure the spectral shifts in the stellar absorption features induced by orbiting planets.

How small are these shifts? A 10 cm/s velocity signal, roughly equal to the RV ‘wobble’ amplitude of the Sun due to the Earth, corresponds to a one nanometer physical shift of the spectral features in the HPF focal plane. This minute shift is roughly equivalent to the lattice spacing of the HgCdTe absorbers on the face of the HPF detector. In real world terms, that’s ten thousand times smaller than the width of one strand of your hair!

We’ve discussed methods of stabilizing the physical environment within the HPF cryostat (see previous posts), but it is equally important to stabilize the illumination inside the spectrograph. Think of it this way: any change in how the light is distributed as it enters the spectrograph will be misinterpreted as true changes in the star, whereas it is actually caused by the journey the light takes through Earth’s capricious atmosphere, the telescope mirrors, and other systematics along the way. Any spatial variation of the light profile illuminating the instrument optics within the cryostat will actually masquerade as spectral shifts on the detector, degrading measurement ability.

Optical fibers have long been used in the telecommunication industry as an efficient method of transmitting large amounts of data over long distances. As such, the quality and availability of these high performance waveguides has increased significantly in the past several decades. This is particularly true in the near-infrared, where fiber transmission is highest due to minimal scattering and absorption.

Typical losses in decibel per kilometer for several generations of optical fiber. Losses are minimized for wavelengths in the near-infrared. Image credit: Olson-technology

In astronomical applications, having such high quality waveguides allows us to collect light at the telescope focus and deliver it to the instruments at more convenient locations. This becomes very pertinent when you consider large, heavy instruments that cannot be suspended at the telescope prime focus. As a result, developing astronomical instruments with optical fibers has become increasingly common. In the case of our HPF instrument, we use over 100 feet of optical fiber to deliver light from the HET focus to our spectrograph room in the telescope basement (with minimal transmission losses.)

A benefit of using an optical fiber to deliver light from the telescope to the spectrograph is improved ‘scrambling’. Standard circular core optical fibers used in astronomical instruments have the convenient ability to ‘scramble’ light, producing an output illumination that is significantly decoupled from the input illumination on the fiber face, as shown in the animated data below. However, for HPF we need even higher levels of illumination scrambling.

Data showing variations in input illumination mimicking a star moving across the fiber face (top) and output illumination (bottom) of the same single circular fiber.

Firstly, the star will certainly not always be centered on the fiber face as the light enters – it will wander around as the layers of the atmosphere shift and as the telescope moves around. This is a critical aspect in any precision RV work, but is particularly important for the HET, which has a fixed zenith angle. This means that the starlight will also fall on different parts of the primary mirror throughout the night and the seasons, so the illumination varies in an additional way compared to other telescopes. Excellent scrambling will dampen all these variations and allow the spectrograph to always be presented a stable, homogeneous illumination.

Octagonal fibers have already started to find a place in astronomical instrumentation to boost scrambling performance. The geometry of these fibers yields a much more efficient redistribution of propagating light relative to standard circular fibers. However, HPF needs even more scrambling than circular and octagonal fibers can achieve. The traditional way to add more scrambling into the system is to use a ‘double scrambler’ which essentially interchanges different angles of lights rays with different positions of light rays (a Fourier transform). This allows the light to be ‘scrambled’ twice using two separate fibers (leading to the name ‘double-scrambler’). However, these optical scramblers are generally lossy and impractical for a complex optical system that needs every bit of available light.

Simulated illumination of HET mirror during a stellar ‘track’. As the star moves across the sky during the course of a night, different portions of the mirror are illuminated. If uncorrected, this will lead to sinister shifts in spectral features in the instrument focal plane.

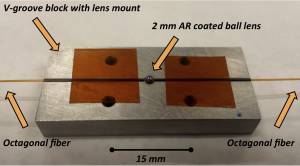

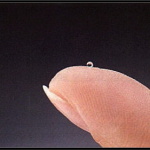

Our solution to this issue comes in the form of a tiny ball lens that is made of an exotic glass with a high refractive index. Specific glasses that have a refractive index ~ 2, in the wavelength range of interest, will focus incoming light onto the back surface of the ball itself. This allows the fibers to be coupled in direct contact with the glass, minimizing alignment problems and transmission losses. This compact and innovative new form of the traditional double scrambler is therefore much more efficient (>85% throughput) and versatile enough to be easily adapted for other fiber-fed instruments.

Our ball lens optical double scrambler. The two optical fibers on either side of the lens are just barely in contact with the ball surface. Fibers are held to the mounting block with glorified scotch tape.

Data showing variations in input illumination (top) and output illumination (bottom) through our complete scrambling system. Look at that stability!

One metric frequently used to gauge the level of homogeneity achieved is the “scrambling gain”, defined as the ratio of the shift of the star on the input face of the fiber versus the centroid shift in the output of the fiber. Typical circular fibers yield scrambling gains of around 10 – 100, while octagonal fibers can yields gains up to ~300. For HPF, we really need scrambling gains of at least 5,000 in order to not be dominated by this source of error.

How well does our system perform? With a combination of octagonal and circular fibers, in addition to our small double-scrambler, we’re able to demonstrate scrambling gains of over 20,000! The true gain is likely higher, since we’re limited by our laboratory measurement precision.

This new technology not only enables the primary science of HPF, but could be immediately applicable to other high-precision instruments as well. For more details feel free to check out our recently published paper.

RSS - Posts

RSS - Posts