It is important to remember that the team building HPF is not comprised of technicians dispassionately filling an order for a new machine, but instead includes many of the scientists who will eventually use the spectrograph for their own research. We believe these collaborators’ enthusiasm for HPF’s science capabilities will be reflected in their contributions to the instrument, resulting in a spectrograph that is both better built and better used.

In addition to documenting the progress of the HPF build, we have taken the time on this blog to detail a lot of the exciting scientific research being produced by the team, in part because we find it especially gratifying to share our results with the public. With that in mind, we are delighted to announce that two separate research projects led by HPF team members were selected to appear in Discover Magazine‘s top 100 science stories of 2014!

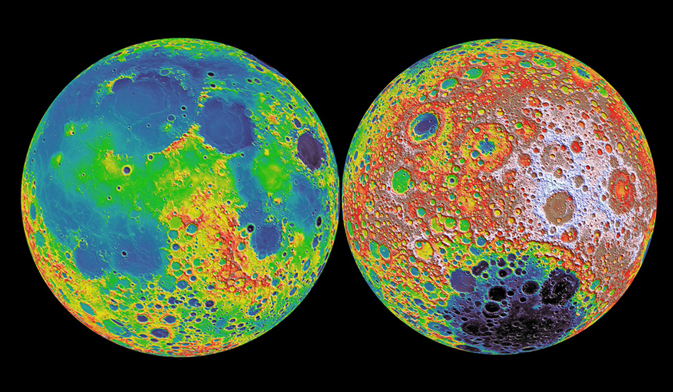

First, appearing at #59 is the exciting story of how Arpita Roy, Jason Wright, and Steinn Sigurdsson solved the 55-year-old mystery of why the far side of the Moon’s surface looks so different from the side we see from Earth. The far side has a much thicker crust, and fewer of the dark “maria” like those we see in the face of the “man in the moon.” According to Arpita and her collaborators, the difference can be explained by the increased temperatures on the Earth-facing side due to the heat radiating off the Earth, which was quite hot following the giant impact that formed the Moon. You can get the full details of their work on Jason’s blog, or in the research paper.

Images of the near (left) and far (right) hemispheres of the Moon, from NASA’s GRAIL mission. Red/white colors indicate higher elevations, while blue/purple colors reflect lower elevation (Image courtesy NASA/GSFC/MIT/LOLA).

Also sliding in as part of #100–which documents the year’s notable exoplanet arrivals and departures–is our work on stellar activity in the Gliese 581 exoplanet system. This entry includes HPF team members Paul Robertson, Suvrath Mahadevan, Michael Endl, and Arpita Roy, thus marking Arpita’s second appearance in this year’s top 100 list!

As you can see, it has been quite a year in science for the HPF team. Here’s to pushing back the frontiers even more in 2015!

RSS - Posts

RSS - Posts